Shawn

Meet Shawn, my Remote Controlled Lawn Mower.

Shawn, 2025

About Shawn

We own this steep 5-acre field on Dartmoor where we graze our horses. As horses are not very good at grazing off weeds, it needs topping twice a year to keep the grass in good condition. When we bought the land, it was very neglected, with a lot of high bramble growth and bracken which took weeks to clear. As it’s too steep for tractors (Most of it is about 30’, with parts up to 45’) my wife and I did this ourselves using petrol strimmers. It took months of work to get it in a state good enough to call the fencers in, and they too struggled with the grade.

I did try mowing it with a ride-on mower, and that flipped over backwards on top of me. Then I bought a tracked mini tractor with flail, which was downright scary to drive on those slopes. After a few years of struggling to strim it, I went to the Royal Cornwall Agricultural Show in 2016 and they had a very shiny remote-controlled bank mower on show. I saw this amazing machine and was very excited! But it cost £45,000 so was obviously out of the question. After spending a few months thinking about this, I started to plan building my own. This has led to a project now around a decade long made up of many variations.

Today, there are a great many more options available, with small versions flooding the market from China for around £2,000. I’m sure these are great, and anything is better than manually strimming this steep ground, especially as one gets older. I’ve probably spent around that on this project overall, although it’s provided a lot of fun and learning by doing it myself.

Specifications

The current version of Shawn that I’m using to mow the field has these key points:

-

A Honda 5.5hp engine from an Alko self-propelled mower, which cost £45 off ebay.

-

Four wheelchair motors in two pairs.

-

A chassis made mostly from the frame of a home treadmill, reinforced with bits and bobs - like some angle iron, wooden 4x2’s, a strimmer shaft, some plate steel, the handle of the original mower and some water pipe.

-

Batteries are similarly mismatched:

- 2x ordinary car batteries. (Now quiet weak)

- 2x Deep cycle electric wheelchair batteries.

- A 24v pack made up of 12x deep cycle 10AH 12v batteries from a UPS that was replaced.

These three “packs” each produce 24v which is combined in a junction box, and connected to the control box with Anderson plugs.

-

A Sabertooth motor driver.

-

A cheap remote controller.

A full tank of petrol lasts about 90 minutes, which is about the same time it takes for the batteries to drop below 24v on this steep ground. It’s conveniently the time it takes for me to need a cup of tea. The Batteries take around 6 hours to recharge, so it’s one session a day, which is about half an acre when it’s fairly easy going. The whole 5 acre field takes 10 or so mows to completely do it.

Mistakes made

There are many - this has been a long process of learning.

- A big “Stop Button”

Burned out on the third day of use. Despite claiming to be able to handle 100 Amps, it melted way before then.

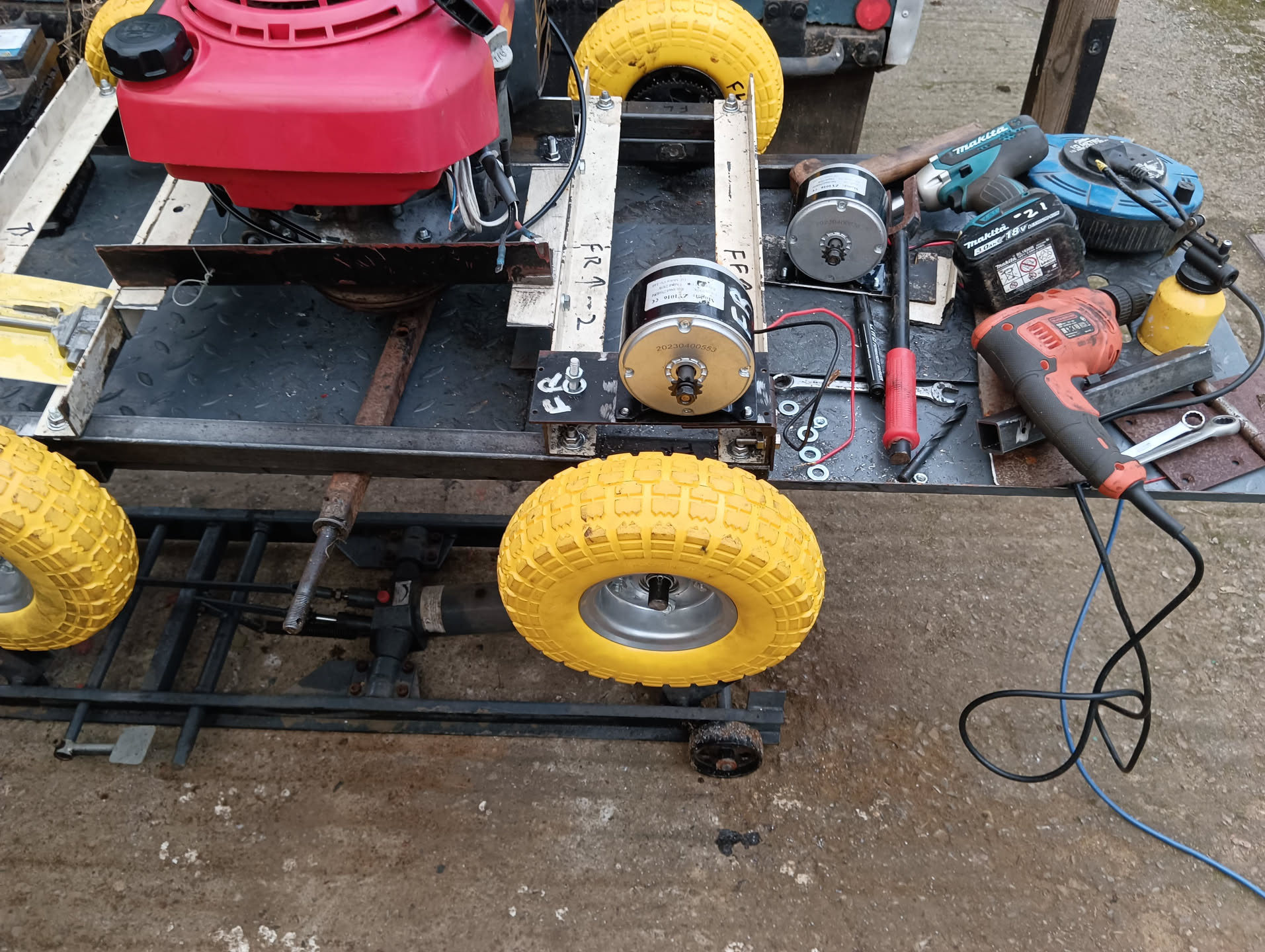

- Ungeared 500w motors connected with chains

Using mini-moto parts to connect a 500w motor above each wheel connected with chain and sprocket. I just couldn’t get the chains to stay on - my engineering skills weren’t up to making everything align well enough or robust enough to survive.

Similarly, using a motorbike chain and sprockets to a single large wheelchair motor to power two wheels on one side didn’t work either. Getting everything to stay aligned proved impossible for more than a few hours.

- Single front wheel

On flat ground, this worked well. Two wheelchair motors at the back and a big castor wheel at the front. But on any kind of rough ground it started to struggle, and taking it onto the steep ground proved it useless. Constantly struggling for torque and the front constantly steering sharply downhill.

- Large wheels

I made large wheels (24") entirely from metal with spade lugs. These shook themselves apart!

I then made wooden wheels out of fence rails and gave them angle-iron tyres with bolts screwed in for grip. Again, these worked okay on flat ground, but were not workable on the steep.

- Keeping the original mower deck

The first few generations meant trying to fix wheels and motors and controls onto the cast aluminium mower deck. This was really hard as the angles were all over the place. I don’t know why I didn’t think of it before, but removing the engine and putting it on a flat piece of steel, and that onto a rectangular chassis, made life so much easier!

- Adding a strimmer

I did mount a strimmer head powered by a 12v motor to the side, so it could trim up against hedges, but 12v was too weak and the positioning too limited.

- Using a 24v alternator

This actually kind of worked. I used the pulley on the centre shaft that was designed to run the mower’s rear wheels and placed an alternator on that - initially at the rear and then at the front to help weight balance. It extended the runtime of the batteries by about 40% but I removed it for two reasons:

-

The alternator would get very hot and start binding. I know this was because I was drawing so much energy for the motors that the alternator was running higher than its rated capacity, and on a hot day in sunlight there wasn’t much cooling to be had. This definitely would work on a smaller, two-motor system on flat ground. I figured it was better to add more batteries instead!

-

With only 5.5hp, the mower struggled too much in long grass when it had to power the alternator as well and would bog down very easily. This was very provable by turning it on and off (I had wired a momentary switch to energise the alternator to get it producing power). I figured it took somewhere between 1 and 2 hp out of the motor so I couldn’t use it on anything but the thinner grass.

Future ideas

-

I’m thinking about replacing the chassis at some point to one with less flex. The amount of creaking it does with the weight of the engine and batteries is quite alarming! But so far nothing has snapped too badly.

-

Possibly replace the engine with a more powerful one, and that probably means uprating to a ride-on mower type engine of at least 8hp, preferably 12.

-

Suspension. I’m not smart enough to design this myself, but something like a child’s ATV chassis might be good. To be able to skid-turn effectively, the layout needs to be close to square, but I’m sure something like this could work well.

-

Some way of remotely turning the mower engine on and off. I have electric start on another mower engine, but don’t know how to integrate that into the RC Controller.

Pictures

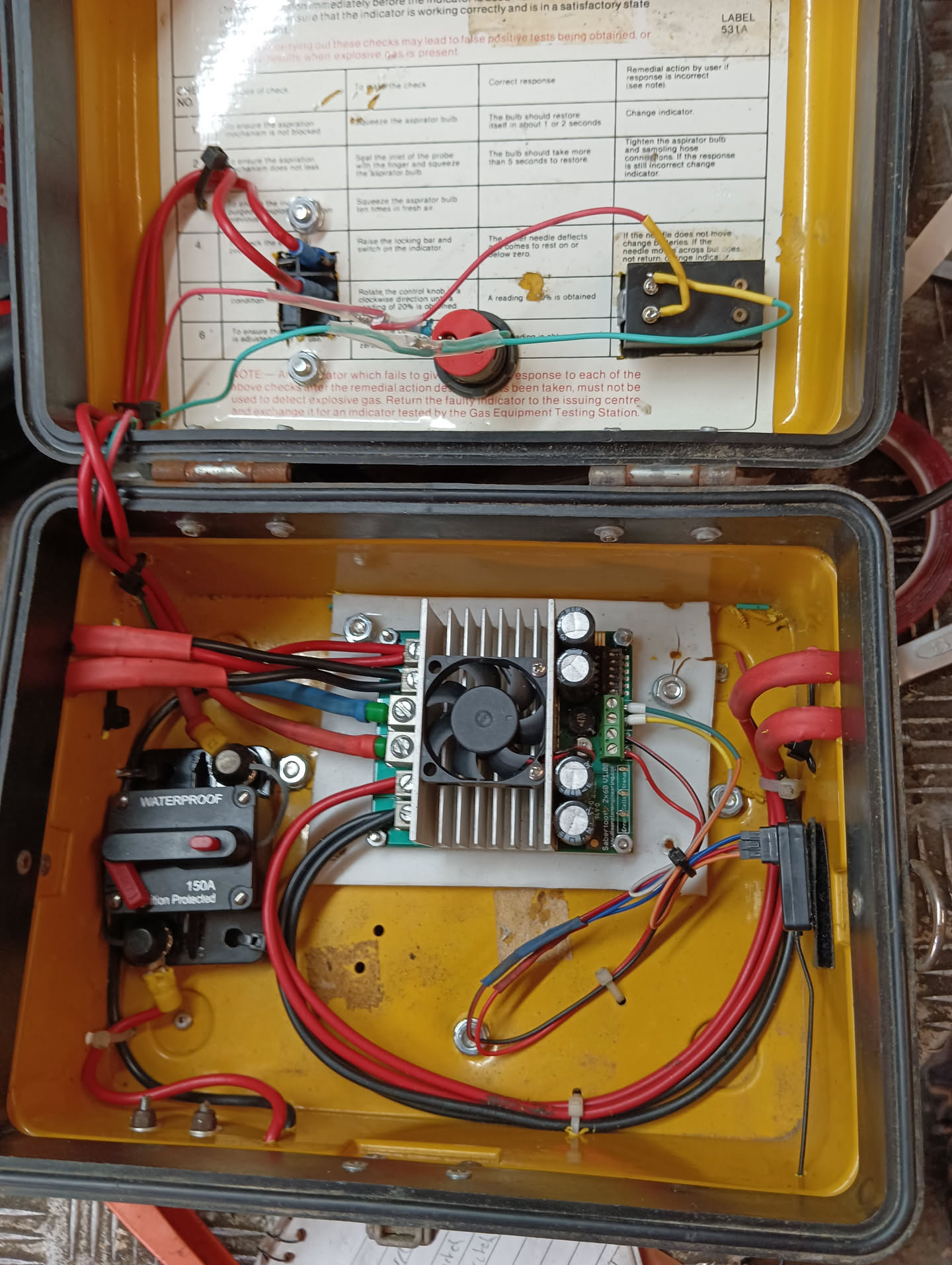

Inside the control box

- Bottom

- A 150A resettable trip (LHS)

- Main Sabretooth controller (An excellent purchase) (Mid)

- The receiver (vecrod to the RHS) This provides as much range as I need.

- Top (Lid)

- LHS Main On/Off Switch (Currently a mains cooker switch)

- A flashing light

- A voltmeter

By the way - the box once contained British Gas inspection equipment. I bought it for a quid at a local auction

Rear view

Showing the flip-out strimmer - too weak a motor at 12v

Lurking in the trees

Working the fields. Note remote control

Previous versions

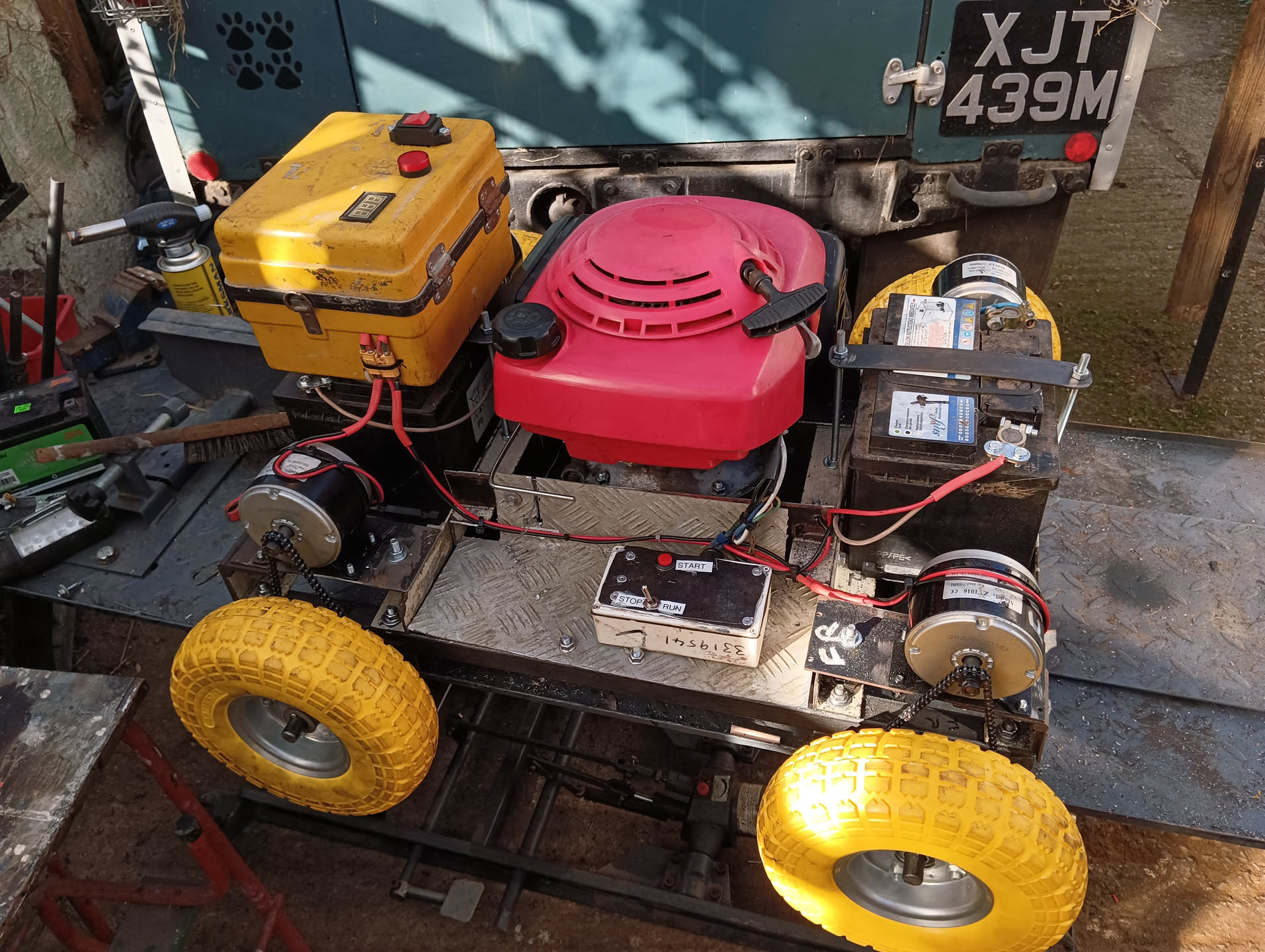

Chain drive on my chassis. Showing electric start box

Chain driven chassis, finished but flawed

Again, from side

Working out motor placements

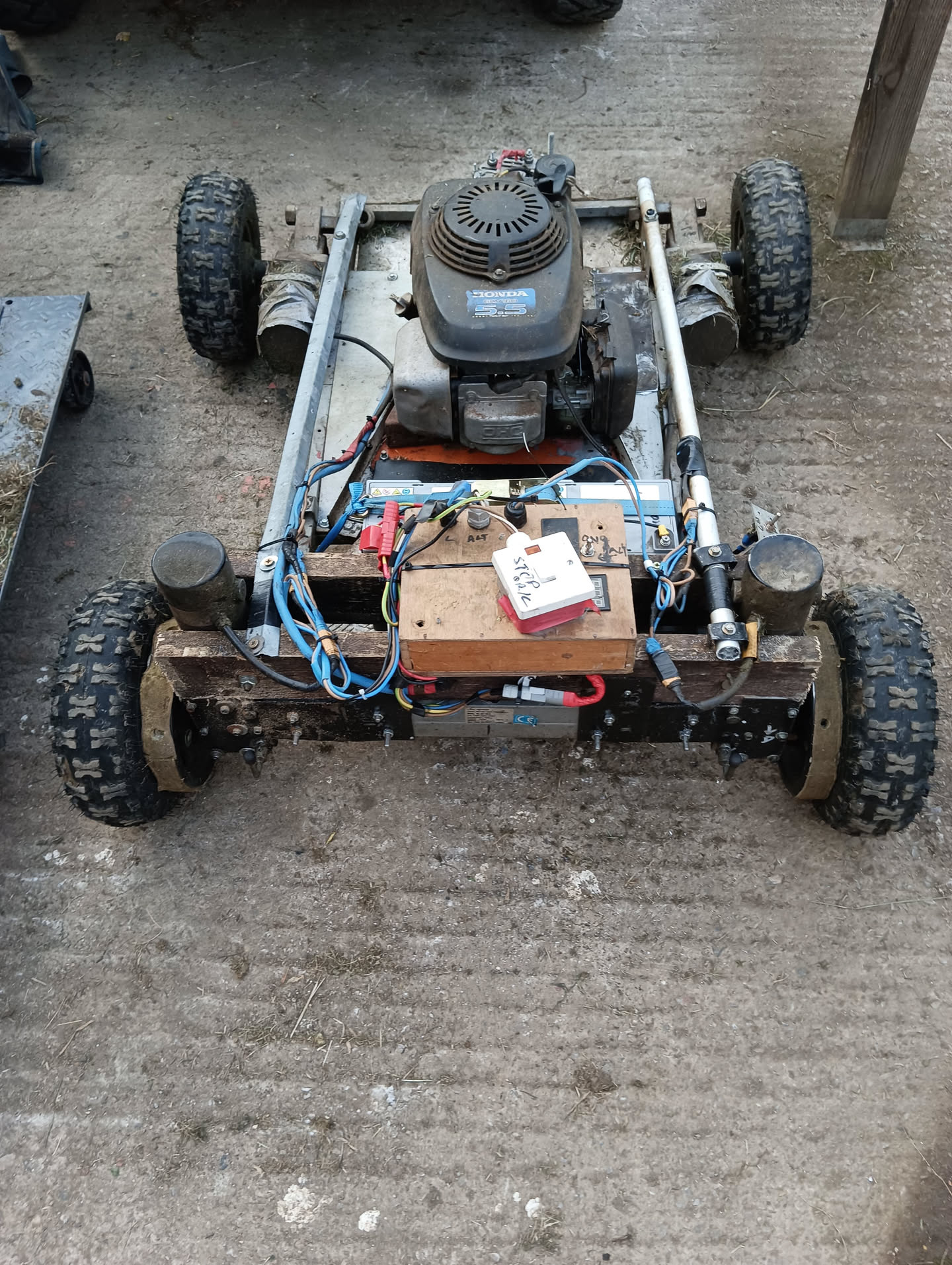

Four motors. Alternator. This was the first shape that worked well on the steep

Mad Max inspired

Wheelchair and treadmill

Basic form of today’s model

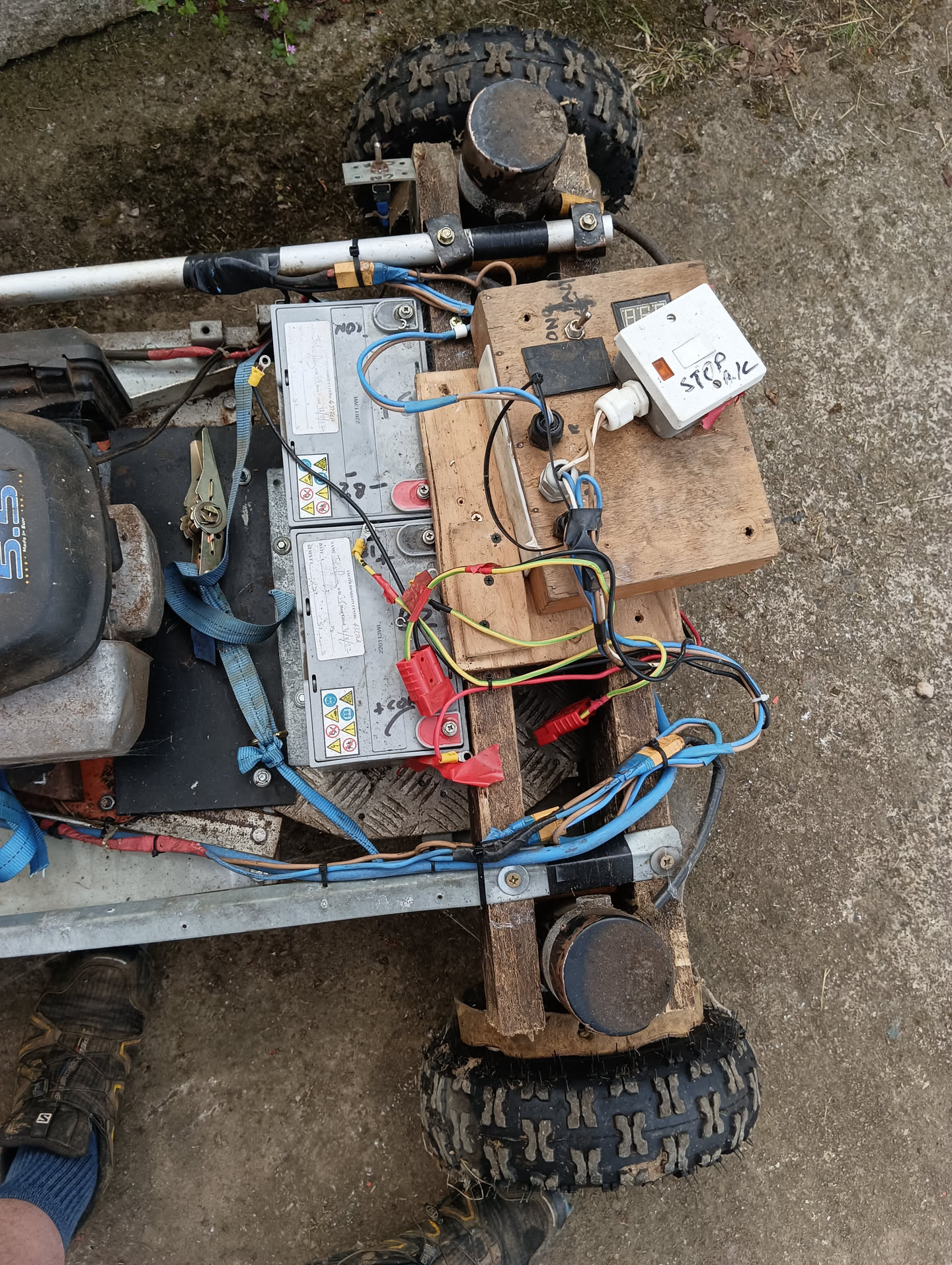

Rear alternator placement and some untidy wirying

Before moving the gas box, which can be more easily removed

Showing front alternator placement

Mounting the wheelchair motors to the original deck was a challenge

Finally moving the engine away from the curvy deck

Videos

An early version, still based on mower body with alternator.

This never made it to field testing.

More videos - Hosted on Imgur as too large for Cloudflare Pages